Comprehending Cutting Conditions To Maximize Boring Bar Performance

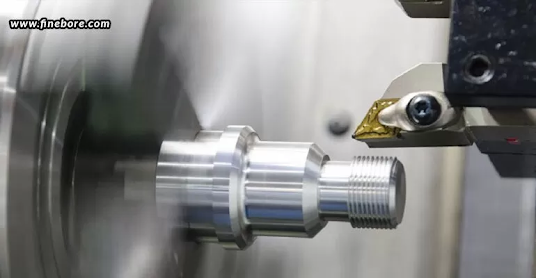

Cutting parameters have profound effects on the performance of boring bars, which are essential equipment in precision machining. By fine-tuning these variables, you can guarantee effective material removal, improve surface quality, and prolong tool life. In order to get high-quality results and preserve tool integrity, cutting conditions must be properly optimized. Cutting conditions define the interaction between the cutting tool and the workpiece during machining. This tutorial examines the effects of feed rate, spindle speed, and cutting depth on boring bar performance and offers helpful suggestions for modifying these parameters to achieve optimal results.

Read More: Comprehending Cutting Conditions To Maximize Boring Bar Performance

Comments

Post a Comment