Expert Advice On Troubleshooting Common Issues With Boring Heads

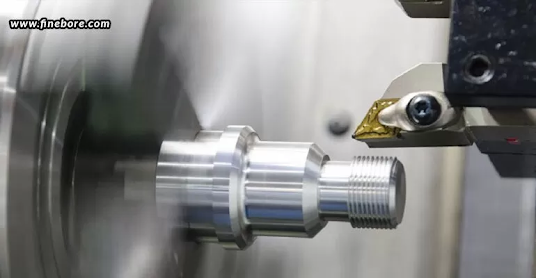

In order to attain tight tolerances and expand holes to precise dimensions, boring heads are crucial equipment in precision machining. Nevertheless, machinists frequently face a variety of difficulties while utilizing boring heads, despite its significance. It’s essential to comprehend these typical problems and know how to solve them if you want to keep up productivity and guarantee excellent outcomes. We’ll go over some of the most typical issues with boring heads in the blog below, along with advice from seasoned machinists to help you make the most out of your boring operations. Read More: Expert Advice On Troubleshooting Common Issues With Boring Heads