When and Why Should You opt for Customizing Boring Bars?

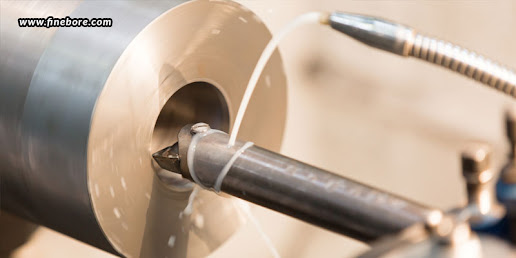

Boring bars are essential tools in machining, providing the precision needed for tasks like enlarging holes and achieving tight tolerances. While standard boring bars are sufficient for many general applications, complex projects often require more specialized solutions. Customized boring bars are designed to meet specific needs, offering advantages like improved precision, optimized cutting performance, and extended tool life. Tailored boring bars can be created to accommodate unique geometries, materials, or specific machining conditions, ensuring better results and reducing the need for frequent tool replacements. Choosing customized boring bars for complex tasks can significantly enhance machining efficiency and the overall quality of the finished workpieces. Read More: When and Why Should You Opt for Customizing Boring Bars?